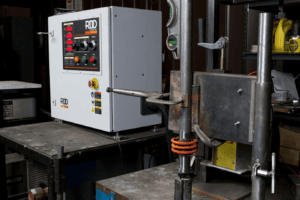

Since 1989, Cook-Leitch Inc. has specialized in Split-Seam, Butted-Seam Tubular Spacers and Bushings. This high-speed stamping technology transitions coil stock material into a precision Split-Seam Tube. This offers a significant cost-savings opportunity vs. that of cut-off tubing and/or a machined spacer/bushing. In addition, we can produce your production Split-Seam Tube without tooling cost—thus, ease of entry for approval and capitalizing immediately on the cost-savings.

Split-Seam, Butted-Seam Tubular Spacers and Tube Fabrications

Manufacturing Capabilities for Split-Seam Tubular Components:

- High-speed stamping presses.

- Tonnage range from 35-ton to 120-ton.

- Size Capabilities of our Split-Seam Tubular Components:

- Overall Length: .250” (6.25mm) up to 6.000” (152mm)

- Inside Diameter: .109″ (2.77mm) up to 1.530″ (38.86mm)

- Outside Diameter: .171” (4.334mm) up to 1.75” (44.45mm)

- Wall Thickness: .020” (.5mm) up to .187” (4.75mm)

- Tolerance Range of Split-Seam Tubular Components:

- Length: +/- .010” to .015” (.254mm to .381mm)

- Inside Diameter: +/- .005” to .010” (.127mm to .254mm)

- Outside Diameter: +/- .005” to .015” (.127mm to .381mm)

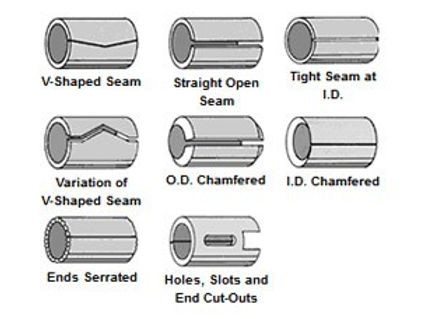

Our Split-Seam Tube Forming Capabilities Include:

- Chamfers

- O.D. Chamfered—Open or Closed

- I.D. Chamfered Seam

- “V”-Shaped Seam

- Cross-Holes

- Punched Holes

- Notched Holes

- Oval Holes

- Cut-Outs in the middle or end of the tube

- Ends Serrated

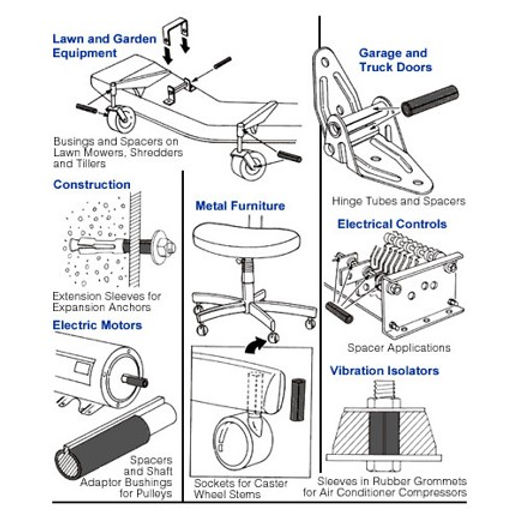

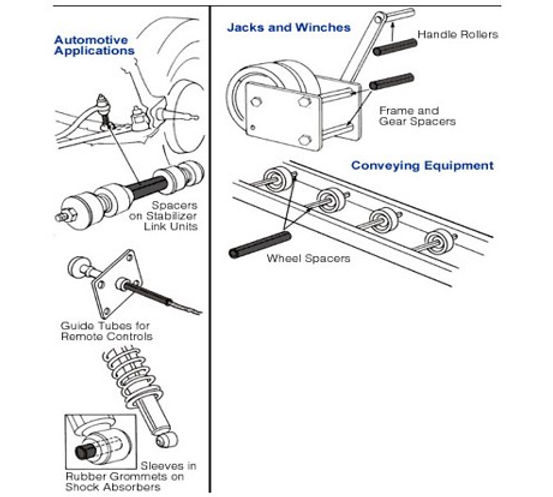

Split-Seam Spacers & Butted-Seam Bushings’ Applications:

- Cook-Leitch Inc.’s custom split-seam tubing capabilities support a wide range of applications.

More applications…………..

- Compression Limiters

- Dowel Pins

- Slotted Spring Pins

- Stand-Offs

- Alignment Bushings

- Fastener Components & Inserts

- Mechanical Supports

- Split Seam Spacers

- Split Seam Bushings

- Connecting Solutions

- Bolt and Shaft Spacers

- Precision Shims & Housings

- Injection Molded Inserts

- Sleeves & Spacers

- Brackets & Clips

- Spring Pins

- Electrical Contacts & Terminals

- Wire & Tubing Connectors

- PVC Water Pipe Stiffeners

- Power Switch Components

- Fastening Solutions

- Anti-Vibration Spacers

Our High-Speed Split-Seam Tubular Stamping Capabilities Utilizes a Variety of Materials:

- Aluminum

- Brass

- Copper

- Pre-Galvanized

- Low & High Carbon Steel

- High Strength/Low Alloy

- Spring Steel

- Stainless Steel

- Aluminized (T-1-25)

We offer plating, heat treating and secondary processes:

- Zinc, Zinc Nickel, Zinc Iron plating

- Zinc Phosphate

- Electro-less Nickel

- Powder Coated & Wet Paint Coatings

- Teflon-Coated

- Heat Treating

- Machining and/or Centerless Grinding

Our Competitive Edge in the Split-Seam, Butted Seam Tubular Marketplace……..

Speed to Market Is Our Commitment to YOU!!

- Our split-seam, butted-seam tubular stamping technology requires

- NO TOOLING COST.

- Our engineering team designs & builds the mandrel tooling in-house.

- We can provide production intent split-seam tubular samples in a matter of weeks.

- Once the split-seam tubular product is approved and in-production, we can build product to your firm and forecasted production schedules.

- We work closely with all our customers to develop a smooth JIT/KANBAN production-delivery system—minimizing our customer’s inventory carrying costs.

Quality-Driven Organization:

- Cook-Leitch Inc.’ Split-Seam Tubular manufacturing facility is ISO9001:2015-registered.

- We have a robust APQP and PPAP sample submission process.

- We engage our customers in our APQP and PPAP process. We understand the application!

- Our manufacturer is a lean-organization, and our responsiveness and customer’ communication is excellent.

Industries Served:

- Appliance

- Motor & Transmission

- Conveyor & Material Handling

- Fluid Power & Hydraulics

- Heavy Truck & Bus

- Garage Door & Transportation

- Metal Stamping

- Lawn & Garden

- Automotive

- Agriculture

- Meters & Switches

- Fasteners & Kitting

- Plastic Injection–Inserts

- Green (Alternative) Energy

Allow Cook-Leitch Inc. to support your Split-Seam Tubular Component’ Needs!!

Since 2017, Cook-Leitch Inc. has partnered with a leader in the tube forming, welding, and tube assembly industry. Our manufacturing partner is an ISO9001:2015-certified, family-owned, one-stop tube fabrication manufacturer. Since 1960, they have built a reputation for producing high-quality precision fabricated tubular components and assemblies for a variety of industries. This Ohio-based facility is vertically integrated with tube bending, CNC machining to produce fittings, MIG/TIG welding & brazing capabilities, and in-house powder coating services. Cook-Leitch Inc. looks forward to supporting your next tube fabrication/assembly project!

Tube Forming Capabilities:

Our capabilities include bending a wide range of tube sizes (i.e. round, square, oval, & rectangular shapes) from 3/16″ O.D. up to 5″ O.D. Our experienced team utilizes our CNC and manual draw bending equipment to fabricate simple 45-degree and 90-degree bends, as well as tubes with complex, multiple plane (3D) bends. Our CNC bend radius ranges from 5/8” to 12” diameter and we specialize in low volume (50, 100, 200 pcs.) to high volume (2,500, 5K and 10K pcs.) production quantities. In addition, we support customers with part design assistance.

In addition, we offer secondary tube fabrication operations such as:

- Single Flare

- Double Flare

- Bubble Flare

- Expanding

- Notching

- Par Flange

- Swaging

- Coping

- Beading

- Flattening

- Milling

- Punching/Piercing

- Slotting

- Threading

- PEM Nut, Rivet Nut Weldments

- Flow Drilling & Tapping

- Machining

- Drilling

Our Core Competency also provides MIG, TIG & Spot Welding along with Brazing (Copper, Nickel and Silver Brazing) of End Fittings to Formed Tubing.

Note: We possess in-house High Pressure I.D. Flushing capabilities to clean the I.D. of each tube fabrication. We can handle up to 20 feet lengths to meet your cleanliness requirements.

Raw Materials of Tubing We Commonly Bend, Weld, and Fabricate:

CNC Machining of Fittings & Manifolds Are a Perfect Complement to our Tube Bending, Welding, and Brazing Capabilities:

- The CNC machines support our tube fabrication business.

- Our manufacturer has Vertical and Horizontal mills, CNC’ machining centers, and lathes to meet a wide variety of machining requirements.

- Featuring well-known names like Mori Seiki, Leblond Makino, Chevalier Suga, and Takisawa.

Types of Coatings & Plating Routinely Applied to Tube Fabrications:

- Zinc Plating—Yellow, Clear, Olive Drab, etc.

- Zinc Nickel

- Zinc Iron

- E-Coating

- Powder Coating (In-House)

- Zinc Phosphate (In-House)

Our Commitment to You is Producing High-Quality Tube Fabrications & Assemblies:

- Our tube fabrication partner is ISO9001: 2015

- We possess CMM’ tubular inspection machines

- Very detailed dimensional layout via our Faro Quantum Inspection machine.

Industries Served:

Cook-Leitch Inc.’s tube fabrication source has developed a variety of tube fabrications and turnkey tubing welded components to support the following industries:

- Agriculture

- Alternative Energy (EV, Solar, Wind)

- Construction & Heavy Equipment

- Fluid Power & Hydraulics

- Furniture

- Material Handling & Conveyor

- Medical

- Military & Defense

- OEM Off-Road

- Transportation