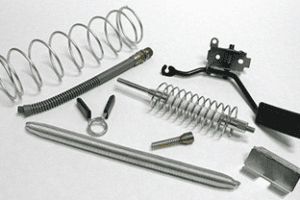

Springs, Wire Forms, Stampings, & Assemblies

Since 1964, the year Cook-Leitch Inc. was established, we have specialized in Springs, Wire Forms, Small Stampings, and Assemblies. If your application requires “round” or “flat” coil stock we can most likely produce your custom component. We can provide technical support for part design, material selection, and proto-type development through the production phase. We will respond quickly to your needs!

- Springs (Antenna, Compression, Garter, Torsion & Extension)

- Hose Guards, Coil Guards, Spring Guards

- Wire Forms (4-Slide and CNC Formed)

- Straight-n-Cut Wires, Pins, Rods, Knurled Pins, Headed Rods, etc.

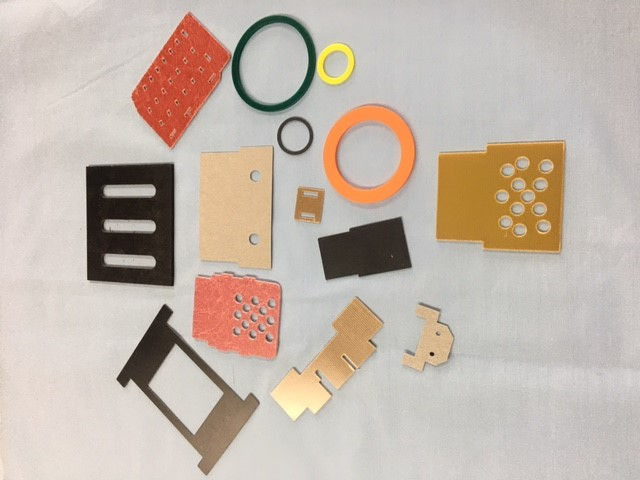

- Stampings (Metallic & Non-Metallic)

- Up to 150 Ton…….

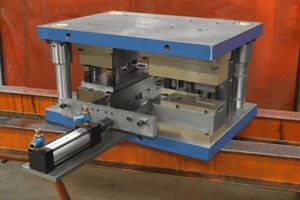

- Multi-Slide, Progressive Die, & High-Speed Punch Press

- Assemblies (Welding–MIG, TIG, Resistance)

Our Manufacturing Capabilities:

- Springs – wire sizes from .005” – .312” diameter.

- Stampings – multi-slide equipment, progressive die, and high-speed punch press up to 150 Ton.

- Non-Metallic Stampings – material from .005” – .250” diameter.

- Wire Forms – Four-slide and auto CNC-forming of wire size up to .551” (14mm) diameter.

- We also have secondary process capabilities such as flattening, piercing, coining, hole-punching, welding of clips, brackets, and metal finishing (i.e. powder coating, painting, zinc plating, etc.).

- Welded Assemblies – production welding of sub-assemblies.

- Welding of two (2) wire-forms, or a stamping to a wire form. Also, riveting, light assemblies and specialty packaging.

Engineering & Technical Support:

- We are responsive to customer’ needs & RFQ’s!

- We have 70+ years of engineering experience working round-wire and flat coil stock materials.

- We provide our customers prompt part design assistance, spring design support, raw material recommendations and proto-typing based upon your application.

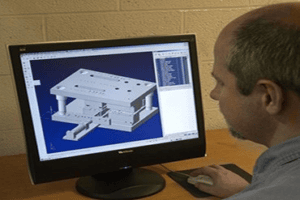

- We design our wire form and stamping tools in-house.

- Our engineering team works with a variety of raw materials:

- 1008/1010 and 1018/1020

- Pre-Galvanized

- Music Wire

- Chrome Vanadium & Chrome Silicone–Valve Quality (Hydraulic Spring Applications)

- Stainless Steel

- High Strength, Low Alloy (HSLA)

- 1045 Cold Headed Quality (Automotive Strikers)

- Copper & Brass

- We offer our customers the best in 3D modeling, prototyping, and technical support in the design of custom-made parts to meet your applications.

- We utilize advanced CAD technology/tools, machines and manufacturing processes to meet each Spring, Wire Form, Stamping & Welded Assembly specification.

Our Commitment to Customer Satisfaction-The “Perfect Formula”!

- Early Involvement in the Design of Springs, Wire Forms, Stampings & Assemblies.

- Advanced Product Quality Planning at time of Product Launch (at time of PO)

- Disciplined Pre-Production Approval Process (PPAP) submitted to our customer.

- Check and Balance Systems throughout the Manufacturing Process.

- Excellent Lot Control……….from Receipt of Raw Material to our Warehouse to you (our customer).

A Culture of Quality Since 1951:

- We are AS9100D-registred (Aerospace & Defense), as well as ISO9001:2015.

- We are registered with the U. S. Department of State Directorate of Defense Trade Controls (ITAR) and the U.S. / Canada Joint Certification Office for Military Critical Technical Data.

- Aerospace & Defense is only 12% of our overall business. However, our disciplined AS9100D-certified quality system pertains to all customers & industries that we serve.

- We incorporate a very thorough product launch (APQP) approach for every new part order or part change.

- Our APQP meeting entails an in-depth analysis of the part dimensions, tolerances, manufacturing methodology, outside sources, and packaging, and shipping.

- This APQP meeting includes team-members from our engineering, manufacturing, purchasing, quality, logistics, and outside processes (heat treat, painting/powder coating, plating, shot-peening, etc.)

- The combination of our disciplined APQP approach, our robust PPAP, manufacturing & quality system, and our Kanban/JIT warehouse makes us a valuable asset to all of our customers.

- We produce high-quality Springs, Wire Forms, Stampings and Assemblies.

History:

CLI has specialized in springs, wire forms, small stampings & assemblies since 1964. Our Northeast Ohio based factory is privately owned and has built an excellent reputation with customers throughout North America.

Our manufacturing campus is 160,000 sq. ft.

Our three (3) facilities include:

- Plant 1

- Engineering—Part Design Assistance, Proto-type development, etc.

- Produces Springs- compression, extension & torsion

- Grinding Department (of Springs)

- Stress Relief Ovens

- Production Stampings

- Drilling & Tapping machines

- Full Tool Room –- for maintenance & new tool build

- CNC Wire Forming

- Production Welding

- Quality Lab

- Plant 2

- Engineering—Part Design Assistance, Proto-type development, etc.

- Produces Multi-Slide (flat-stock) Stampings

- Wire Forms

- New Verti-Slide CNC

- Wire Forming Machines

- Robotic Welding Department

- Prototype/Secondary Operations for Low Volume Custom Components

- Quality/Inspection Lab.

- Plant 3

- Non-Metallic Stampings—fiber board, glass-filled polymers, vulcanized fiber, NEMA (Electrical) grade materials, polymers (nylons, PP, PE, etc.).

- Gaskets

- Insulators

- Laminations

- Washers

- Hose Guard/Coil Guards – round and flat stock up to 25 ft. in length.

- Finished Goods Warehouse for JIT and Kanban shipments.

- Non-Metallic Stampings—fiber board, glass-filled polymers, vulcanized fiber, NEMA (Electrical) grade materials, polymers (nylons, PP, PE, etc.).

We can manage raw material & finished goods. We do an excellent job managing our customers’ production and delivery requirements, and we maintain an adequate amount of raw material and finished goods inventory to support our customers’ demands.

Industries Served:

- Automotive

- Aerospace

- Fluid Powers

- Transport

- Military/Defense

- Consumer Products

- Lawn & Garden

- Marine

- Medical

- Government

Part Size Specifications:

| Wire Size for CNC Wire Forming Machines | .118" to .551" 3mm to 14mm |

| Capacity for Punch Presses | up to 150 ton |

| Material Size of Thickness | .010 to .093 in |

| Material Size of Wide | 1/8 to 3-5/16 in |

| Material Size of Thickness (Multi-Slide Machines) | .254 to 2.36 mm |

| Material Size of Wide (Multi-Slide Machines) | 3.175 to 84.5 mm |

| Wire Diameter (Four-Slide Machines) | .003 to .312 in .076 to 7.92 mm |

| Coiling Capacty for Spring Coiler Machines | 25 ft |

| Diameter for Torsion Coiling Machines | .010 to .211 in .254 to 5.359 mm |

| Wire Size | .003 to .312 in .076 to 7.92 mm |

| Wire Size for Grinders | .010 to .312 in 14 to 30 in |

| Wire Size For Straighten & Cut Machines | .010 to .250 in .254 to 6.35 mm |

We are a USA supplier!

All our products are manufactured and/or distributed in the USA.

All our products are manufactured and/or distributed in the USA.