Cook-Leitch Inc. can support your Electroless Nickel, Teflon Nickel and Nickel Boron Nitride coating requirements. We can plate molds, tooling, fixtures, and your production components (i.e. machined components, stampings, castings, etc.). We have various plating tank sizes to accommodate the size/configuration of your component. We appreciate your consideration of Cook-Leitch Inc.

Types of Parts We Apply Electroless Nickel, Teflon Nickel & Nickel Boron Nitride Coating:

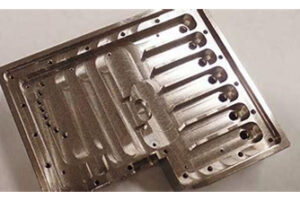

- Molds, Dies, Tooling, and Fixtures.

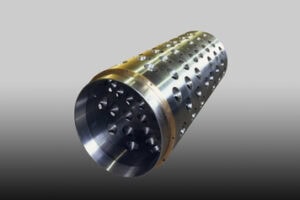

- Machined components (large CNC parts and smaller production higher volume parts)

- Castings

- Stampings (Fine-blank stampings, progressive die, high-speed punch press, etc.)

- Aluminum components

- Sheet metal fabrications

Tank Sizes:

Electroless Nickel –

- 84” x 60” x 48” deep

- Super E-N’ tank line is 120” wide x 120” long x 48” high/deep.

Teflon Nickel –

- 37” x 43” x 60”

Nickel Boron Nitride –

- 24” x 32” x 40”

Electroless Nickel (E-N) plating is applied via an autocatalytic’ chemical reaction vs. an electrical charge (i.e. Nickel’ electroplating). There are (3) basic types of E-N plating:

- Low Phosphorous E-N (Under 5% Phos)

- Mid-Phosphorous E-N (5%-9% Phos)—Our most common E-N type.

- This is the most common E-N’ used in the marketplace.

- Higher Speed Deposition Rate vs. High Phos.

- Improved Aesthetics

- High Phosphorous E-N (10%-13% Phos) Excellent for Corrosion Resistance

There are many benefits of Electroless Nickel plating:

- Increased Hardness with E-N

- 48-52Rc hardness without bake

- 56-60Rc hardness with bake

- Very Consistent Thickness of plating

- Excellent lubricity or reduced coefficient of friction

- Abrasion Resistant

- Very Aesthetic Looking

- Since it’s a “Chemical” vs. “Electrically Charge”, the E-N’ Coating Can Plate in Deep Holes, Recesses, Undercuts, and Small Areas.

- We can E-N a variety of base materials (i.e. Steel (1215, 12L14, 8620, etc.), Stainless Steel, Aluminum, Brass, Copper, etc.