- Rack Zinc Plating

- Rack Zinc Nickel Plating

- Rack Zinc Iron Plating

Rack Zinc Nickel,Zinc Iron & Standard Zinc

Plating Process and Customer' Specifications

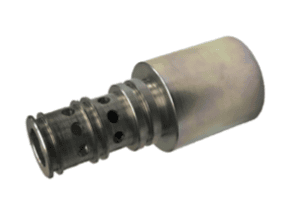

- Our zinc plating source supports the automotive stamping industry, machined component manufacturers, cold-forming/heading, and other OEM component manufacturers with Zinc plating requirements.

- We are centrally located in the Midwest USA and serve customers in Illinois, Michigan, Indiana, Ohio, and Kentucky.

- Our partner’s unique plating process provides excellent corrosion resistance without depositing excessive plating thickness.

- Our Zinc, Zinc Nickel, and Zinc Iron plating process meet a variety of automotive plating specifications, including:

- Bosch

- BMW

- British Standards

- Case New Holland

- Caterpillar

- Continental

- Cummins

- Dana

- Delphi

- DIN-specifications

- Eaton

- FCA/Chrysler

- Ford

- General Motors

- John Deere

- Honda

- Hyundai

- Mazda

- Mercedes

- Navistar

- Nissan

- Tenneco

- Tesla

- Toyota

- Volkswagen

- Volvo

Please contact us about meeting a specific customer plating specification.

There are many other customer’ plating specifications we attain not listed above.

Contact Dan Leitch @ 216-870-1098 or dbleitch@cook-leitch.com

Salt Spray Testing:

- Cook Leitch’s plating source’s salt spray testing lab meets the ASTM B117, JIS Z 2371, and ISO 9227 specifications.

- Here’s what our customers can expect via corrosion resistance with our unique passivation & plating process:

- Zinc plating

- 240 hours or greater to white rust

- 480 hours or greater to red rust

- Zinc Nickel plating

- 360 hours or greater to white rust

- 1,000+ hours or greater to red rust

- Zinc Iron plating

- 168 to 240 hours or greater to white rust

- 720 hours or greater to red rust

- Zinc plating

Cyclic Corrosion Testing:

- In today’s automotive manufacturing industry, there is continuous pressure to achieve increased corrosion resistance based on various corrosive atmospheres.

- Our Zinc Plating Source is committed to simulating environmental changes within a controlled “yet expedited” setting to predict corrosion failure modes better after the part has been assembled.

- Our Quality Lab can perform Cyclic Corrosion Testing to meet the requirements of GMW14872, SAE J2334 and Ford’s CETP L-467 specifications.

- Our Quality Lab is capable of performing Cyclic Corrosion Testing to meet the requirements of GMW14872, SAE J2334 and Ford’s CETP L-467 specifications.

Cook Leitch's Plating Source What makes us Different?

- 70 years of dedicated service to our customers and employees.

- Excellent rapport with our chemical and plating rack sources.

- Our partner is solely focused on our customer’s rack Zinc, Zinc Nickel, and Zinc Iron plating requirements. That’s been our expertise throughout the history of this family-owned company.

- Cook Leitch’s plating source has built a strong reputation working with rubber and stamping companies to develop a zinc plating process for enhanced adhesion bonding rubber-to-metal components.

- We have excellent Lot Control and detailed Work Instructions and Packaging Guidelines for every part we run.

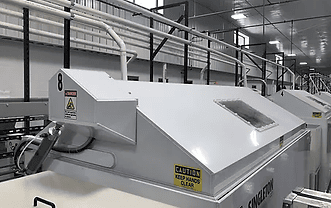

- We are a large enough plating facility to handle high-volume automotive applications. Yet, we’re small & agile to maintain ongoing communication with our customers and respond promptly to our customer’s demands.

- Please consider our zinc plating source on a current and/or future Zinc, Zinc Nickel, or Zinc Iron plating application. We will be a great partner for your organization!!